We particularly recommend PBSS for above knee and knee disarticulation prostheses.

Learn how a PBSS socket with integrated acupressors can help relieve emerging pain.

Make an appointment over the phone or send us a message!

Active, painless, comfortable

PBSS socket system

As a direct link between humans and prosthetics, the socket system plays the central role in a prosthesis treatment.

Because conventional socket solutions were not able to satisfy us, we have created a socket with previously unattainable precision and fit: The Pohlig Bionic Socket System (PBSS). This innovative socket system enables the user to handle different everyday situations more actively, painlessly and comfortably than with previous socket systems.

Depending on the individual circumstances and requirements of the user, additional functional systems (add-ons) can be integrated into the socket.

PBSS socket manufacturing process

From scan to individual socket

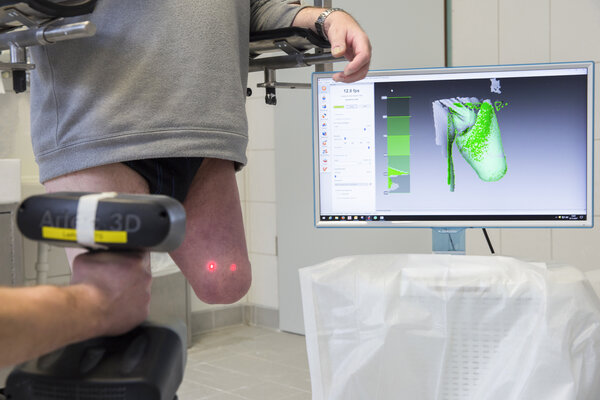

Traditional manufacturing techniques such as gypsum impressions, measuring with the tape measure, etc. have given way to contactless digital scanning. When the muscles are active, the shape of the amputation stump is recorded within seconds via scanner, saved as a three-dimensional file with the stump topography marked accordingly, and then subjected to a virtual modelling process. Compared to the plaster casts used so far, the ratio of contoured stump bed to stump volume can be measured and considered much more precisely.

An essential component of the PBSS concept is the collection of biometric data by means of objective examination or analysis of the residual limb using sonography. The muscular topography of the femur stump is recorded in order to determine the course of the muscles, possible bones or exostoses, but above all the axial muscle gaps. This allows the stabilizers to be positioned precisely and individually in the socket. Stabilizers activate the muscles and significantly improve the guiding performance of the prosthesis.

Based on the biometric data, the 3D modelling of the residual limb scan is then carried out. The finished stump model serves as the basis for the actual socket design.

The prosthesis socket system consists of an inner socket made of HTV silicone and a carbon shell. Thanks to the excellent material properties of the silicone, the inner socket adheres very well to the residual limb. The flexible yet high-tensile-strength silicone edges enable the fixed portion of the carbon shell to be cut out deep in the seat area, which significantly increases comfort. In addition, the core muscles in the flexible HTV silicone inner socket can work very well.

Depending on the respective core ratios, individual compensations can be made in sensitive areas. This allows you to create an optimal fit. Users can choose their preferred color from a wide selection of colors. The end result is an individual socket, where the add-ons below can be included, if needed.

Customize the PBSS socket

Supplementary functional systems (add-ons)

The thigh residual limb volume is not always constant. Diseases, weight loss or sporting activity can result in mismatches between the residual limb and socket intake volumes, resulting in significantly worsening guide properties.

PBSS air enables the prosthesis wearer to adapt the prosthesis socket to the current dimension of the residual limb. The air chambers are integrated directly into the HTV silicone contact socket and can be optimally adapted to the stump shape, thanks to contoured contact surfaces.

The Pohlitherm element biosensor ensures a climate-friendly temperature level, so that the residual limb can feel comfortable in the prosthesis socket – regardless of the outside temperature. Especially in cold-sensitive amputation stumps, the targeted thermal regulation of the residual limb has proven to be positive. The effect of the Pohlitherm element is initially evaluated in the trial socket and is only implemented in the definitive PBSS socket if the user has a positive outcome.

PBSS acupressure is used for pain management. Acupressure is a healing process that is used especially in traditional Chinese medicine (TCM) and is intended to activate the body’s self-healing powers. This is done by applying blunt pressure to defined areas of the body.

The acupressors inside the PBSS socket are positioned along so-called “meridians”. They can be manually activated by the user at the medically determined intervals and thus offer an alternative treatment of pain without the addition of medication.

Unfortunately, residual limb pain and phantom pain often appear together in amputees. The PBSS port system opens up new treatment options for doctors, with the aim of using medications that no longer appear systemically, but locally. For example, prescribed pain therapy can be treated locally on the affected pain area via implied service ports without having to remove the prosthesis. In many cases, local pain treatment is not only significantly more effective, but often leads to a reduction in medication.

PBSS socket

All of the benefits at a glance

For the first time, the musculature receives stabilizers at relevant points, which result in improved guidance of the prosthesis. In addition, the intramuscular stabilizers provide greater control and safety in dynamics. Parallel to the stabilizers, expansion spaces for muscular expansion are taken into account, resulting in a comfortable fit for the prosthesis shaft.

These design principles not only make it easier to put on and take off the prosthesis shaft, but also allow variable adjustment of the shaft volume in the event of a volume change. This also takes into account, among other things, the dynamic deformation of the residual limb.

Following a medical study carried out in cooperation with Pohlig, pain with a PBSS prosthesis socket could be significantly reduced in some cases. Phantom pain was also positively influenced in many cases.

The PBSS prosthesis sockets can be supplemented with various functional units. Depending on the individual circumstances and requirements of the user, various technological add-ons can be used to positively influence the wearing comfort in everyday life.

The best possible connection between the stump and prosthesis socket is achieved by an HTV silicone contact shaft, which can be manufactured in different degrees of hardness and with different adhesion behavior depending on the stump conditions.

The wearers of a PBSS socket greatly appreciate the unobtrusive body-hugging shape of the socket edge contour. There are practically no limits to the individual color design.

With its interdisciplinary approach, the PBSS concept provides for the active involvement of the attending physicians and therapists in prosthetic care in addition to the user. This opens up new perspectives in leg prosthesis treatment.

Feedback

What users say about PBSS

The positive response of our patients treated with a PBSS socket encourages us to continue along the path we have chosen. In a study in which 22 PBSS-treated prosthetic wearers were clinically examined, it was demonstrated that all examined users benefited from PBSS. Patients with a high level of pain even had a higher benefit from this new care technology.

"I have had phantom pain since my amputation. Every 4-6 weeks there was a massive attack that I could only combat with trauma drops – a really high single dose. Since I’ve had the PBSS shaft, I don't have any phantom pain anymore.

The new quality of life with this prosthesis shaft technique gives me more energy for the day. This also allows me to work more concentrated in my profession. I have to use less concentration on walking and can focus on my contact person. That’s a huge win for me."

"My experience is that the guiding of the prosthesis has increased. The seating comfort has also improved considerably – no longer comparable to my old shaft technology. Cycling, bending down, sitting in the toilet... these are all things that are now much more comfortable."

"Years of positive experiences with the shaft that encircled my ischium-ramus initially cost me a lot to overcome for a system change, but I was equally impressed by the significantly more free movement in the pelvic area, and more wearing comfort thanks to low socket edges and the associated improvement in cosmetic conditions. I am particularly pleased that the socket has better adhesion properties despite the lower edges and the increase in freedom of movement, and that I can finally cycle again without my prosthesis slipping."

"I have had an amputated thigh for over 40 years and have witnessed the development of the shaft production from the transverse oval wooden shaft to the PBSS socket on my own body. In my opinion, the PBSS socket is currently the most evolved. In addition, the individual socket of Pohlig is optimized meticulously and with great commitment until it truly fits. This is not a matter of course, but is still so important, as the stump prosthesis coupling represents the limiting factor in the overall quality of care and thus the usability in the everyday life of the amputee."

First introduction of the PBSS system in Munich

After two and a half years of intensive research and development work, Pohlig presented the new Pohlig bionic socket system (PBSS) in Munich for the first time on November 27, 2013, as part of a pre-launch. Around 120 people, including doctors, payers, orthopedic technicians, and users, learned about the new shaft technology.